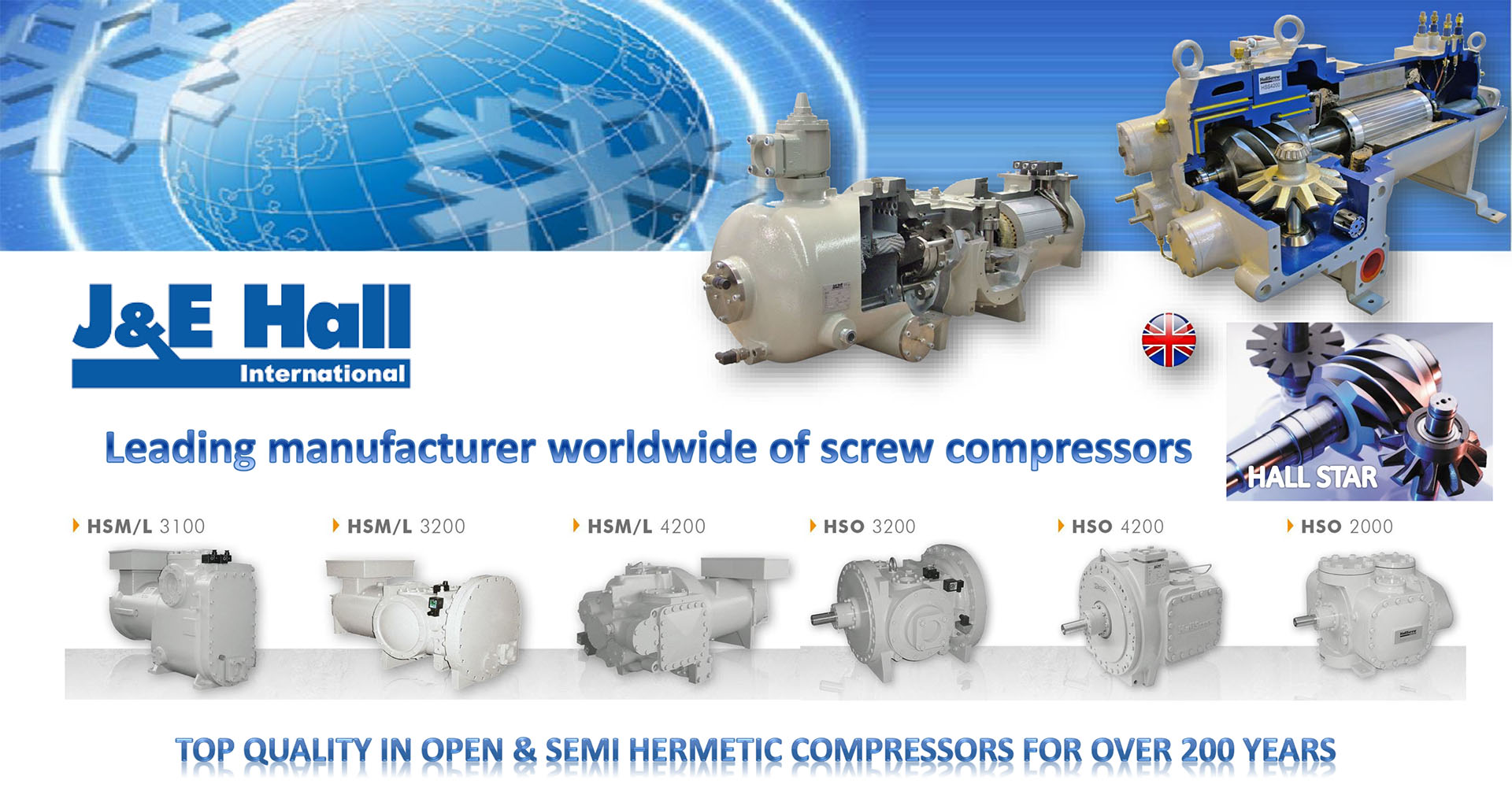

J & E Hall is one of the world’s foremost refrigeration solution providers.

We have been developing refrigeration technology for over 120 years and are able to call upon unrivalled expertise and cutting edge production capabilities worldwide.

This allows us to offer a seamlessly integrated single source of supply and deliver the complete end-to-end service from design and manufacture to installation, maintenance and on-going support.

As a member of the Daikin group, we are reassuringly committed to innovation and the environment. As such, our product and service portfolios continually set the benchmark for quality, reliability and energy efficiency.

Furthermore, as a market-leading organisation, we have configured our operations around five customer-driven business areas. These allow us to focus carefully on Refrigeration for Process Systems, including bespoke refrigeration systems; Installation and Service; Marine Systems; Commercial and Industrial Products and Spare Parts support to provide a level of service that is unparalleled within our chosen markets.

HallScrew Technology …

• Manufactured since 1978

• Over 8,000 installed in over 85 countries world-wide

• Gained awards for outstanding British design and The Queen’s Award for Technological Achievement

• Only three basic moving parts

• Single screw positive displacement compressor designed for industrial refrigeration, air conditioning and heat pump systems

Star wheel…

• J & E Hall use low friction composite material “HallPlas” in the compression process to ensure high efficiency and reliability

• “HallPlas” material was developed using aerospace technology and can withstand the toughest operating conditions with all types of refrigerant

“The HallScrew is a market leader in compressor design”

Benefits

• Single screw technology

• Long established worldwide reputation

• Award winning design flexibility

• Engineered for quiet operation

• Outstanding reliability

• Superior efficiency

• Ease of installation

• Ease of maintenance

• Wide ranging cooling capacities

• Economised

1. Suction Gas fills the rotor flutes before they mesh with the teeth on star wheel A.

2. Compression As rotation continues, the gas is sealed within the space created by the rotor flute, the rotor housing and the star wheel tooth. Continued rotation causes the volume of the rotor flute to reduce, compressing the gas.

3. Discharge As the maximum point of compression is reached, a discharge port is uncovered and all the gas is expelled from the rotor flute. The action illustrated applies to star wheel A. A mirrored action using star wheel B occurs simultaneously on the underside of star B.

Main Features

Positive Displacement Rotary Compressor : Positive displacement means pressure is increased by a reduction in volume. This is the same principle as reciprocating compressors but with a pure rotary motion, hence very little vibration

Single Screw Design : This means that the compressor has a single rotor with two “stars” or “gate rotors” as opposed to twin screw compressors which have two screw rotors

Single Screw Design : This means that the compressor has a single rotor with two “stars” or “gate rotors” as opposed to twin screw compressors which have two screw rotors

Balanced Compression : Compression is taking place on both sides of the main rotor which cancels out radial forces on the main Bearings

Continuously Variable Capacity Control (10% or 25% _ 100%) : The compressor can unload STEPLESSLY to pump EXACTLY the correct amount of gas needed to obtain the required refrigeration duty. This is shown to be a much more energy efficient method of capacity control than any stepped method

Continuously Variable Capacity Control (10% or 25% _ 100%) : The compressor can unload STEPLESSLY to pump EXACTLY the correct amount of gas needed to obtain the required refrigeration duty. This is shown to be a much more energy efficient method of capacity control than any stepped method

There are no products to list.

-275x275.jpg)

-275x275.jpg)

-275x275.jpg)

-275x275h.jpg)

-275x275h.jpg)

-275x275h.jpg)

-275x275.jpg)

-275x275.jpg)