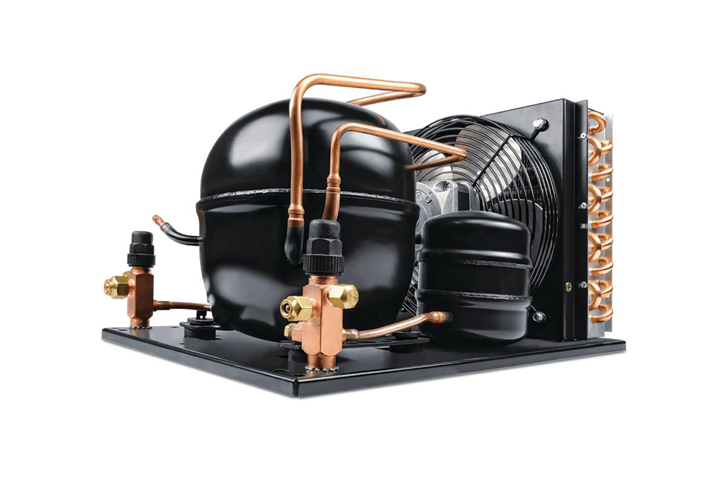

Η συντήρηση ενός συμπυκνωτικού μηχανήματος περιλαμβάνει διάφορα στάδια καθώς θα πρέπει να ελεγχθούν ή/ και να καθαριστούν αρκετά εξαρτήματα. Η συντήρηση ωστόσο μας εξασφαλίζει τη σωστή λειτουργία και την αποτελεσματικότητα του συστήματος.

Θα πρέπει να ενημερώνουμε τους πελάτες μας πως η προληπτική συντήρηση είναι απαραίτητη και παρουσιάζει πολλά οφέλη. Οι καλά συντηρημένες συμπυκνωτικές μονάδες λειτουργούν πιο αποτελεσματικά και καταναλώνουν λιγότερη ενέργεια. Επιπλέον ελαχιστοποιείται ο κίνδυνος αστοχίας εξαρτημάτων ή εξοπλισμού μειώνοντας έτσι τη συχνότητα βλαβών του συστήματος. Σαν γενικός κανόνας, η προληπτική συντήρηση ενός συμπυκνωτικού μηχανήματος θα πρέπει να πραγματοποιείται 2 φορές τον χρόνο, ωστόσο πάντα θα πρέπει να συμβουλευόμαστε το διάστημα συντήρησης που προβλέπει ο κατασκευαστής του μηχανήματος.

Ένα σύμπτωμα της έλλειψης συντήρησης ενός συμπυκνωτικού μηχανήματος μπορεί να είναι η υπερθέρμανση του συμπιεστή. Ο συμπιεστής λειτουργεί με υψηλότερη ένταση με αποτέλεσμα να φτάνει στο σημείο να ενεργοποιείται η προστασία υπερφόρτωσης του συμπιεστή απενεργοποιώντας τον συμπιεστή προτού επιτευχθεί η επιθυμητή θερμοκρασία χώρου, ώστε να προστατεύσει τον κινητήρα του.

Εάν αυτό αρχίσει να συμβαίνει συχνά τα πρώτα σημεία που θα παρουσιάσουν βλάβη είναι τα ηλεκτρικά εξαρτήματα. Όλα τα ηλεκτρικά εξαρτήματα έχουν διάρκεια ζωής με βάση τους κύκλους λειτουργίας τους. Αν λοιπόν οι κύκλοι αυτοί είναι κάθε 1 λεπτό ενώ θα έπρεπε να είναι κάθε 15 σημαίνει ότι τα ηλεκτρικά εξαρτήματα θα εμφανίσουν βλάβη πολύ νωρίτερα. Η βλάβη των ηλεκτρικών εξαρτημάτων είναι πιο συχνή από βλάβη στον ίδιο τον συμπιεστή. Ωστόσο όταν εξακολουθεί να μην υπάρχει η απαιτούμενη συντήρηση και το συμπυκνωτικό μηχάνημα εξακολουθεί να λειτουργεί με πάρα πολλά on/ off κάποια στιγμή θα προκύψει βλάβη και στο συμπιεστή.

Η εκκίνηση ενός συμπιεστή είναι η πιο κρίσιμη φάση στην λειτουργία του. Κάθε φορά που ξεκινάει ένας συμπιεστής έχουμε εντονότερες δονήσεις που επιβαρύνουν τη λειτουργία του. Επιπλέον τα ρουλεμάν δεν έχουν επαρκή λίπανση και δημιουργούνται τριβές και άρα φθορές. Όταν λοιπόν υπάρχουν πολλές εκκινήσεις ανά 24ωρο ο συμπιεστής θα παρουσιάσει συντομότερα μηχανικές βλάβες.

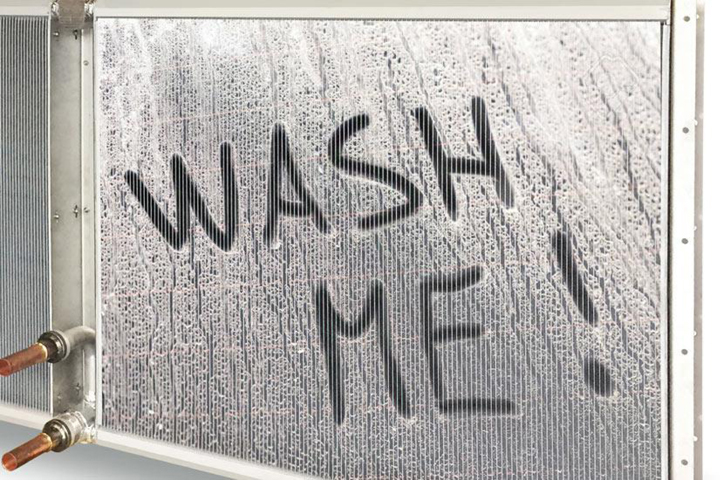

Κατά την προληπτική συντήρηση ελέγχουμε ότι όλα τα εξαρτήματα της συμπυκνωτικής μονάδας είναι καλά στερεωμένα. Αυτό αποτρέπει τη χαλάρωση κάποιου εξαρτήματος αλλά επίσης μπορεί να μειώσει σημαντικά το θόρυβο λειτουργίας του συστήματος. Για την αφαίρεση των συσσωρευμένων ρύπων στον συμπυκνωτή χρησιμοποιούμε ηλεκτρική σκούπα, πεπιεσμένο αέρα ή κατάλληλα χημικά υδατοδιαλυτά ή όχι ( Advanced Engineering), πάντα προστατεύοντας τον περιβάλλοντα χώρο με ειδικά καλύμματα προσέχωντας να μην επιβαρύνουμε τις υπόλοιπες συσκευές τριγύρω, αν υπάρχουν. Επίσης ελέγχουμε και καθαρίζουμε τον κινητήρα του ανεμιστήρα από σκόνες και ακαθαρσίες με ένα πανί ή πεπιεσμένο αέρα.

Εάν το συμπυκνωτικό μηχάνημα λειτουργεί με υψηλή πίεση κατάθλιψης παρά το γεγονός ότι ο συμπυκνωτής του είναι καθαρός το πρόβλημα θα μπορούσε να είναι αέρας ή παρουσία μη συμπυκνούμενων ουσιών στο εσωτερικό του συστήματος. Ελέγχουμε αν υπάρχει βουλωμένο φίλτρο στο σύστημα. Για να σιγουρευτούμε ότι δεν υπάρχει βούλωμα στο φίλτρο θα πρέπει να ελέγξουμε ότι δεν υπάρχει διαφορά πίεσης πριν και μετά από αυτό μεγαλύτερη από 2 psig. Εμπειρικά αν παρατηρήσουμε πάγωμα μετά το φίλτρο χρειάζεται η αντικατάστασή του. Επίσης χρήσιμη είναι η διενέργεια τεστ οξύτητας ώστε να ελέγξουμε αν υπάρχουν υγρασία και οξέα στο σύστημα. Αν προκύψει ότι υπάρχουν θα πρέπει όλη η ποσότητα του ψυκτικού ρευστού να αφαιρεθεί και να γίνει πλήρωση με νέο μετά την αλλαγή του φίλτρου του μηχανήματος και μετά από την επίτευξη ικανοποιητικού βαθμού κενού στο σύστημα.

Αν ο συμπυκνωτής δεν είναι καθαρός σημαίνει ότι η συναλλαγή θερμότητας του ψυκτικού ρευστού με το περιβάλλον περιορίζεται. Αυτό οδηγεί σε λιγότερο αποτελεσματική λειτουργία του συμπιεστή και σε έλλειψη υπόψυξης. Για να ανταποκριθεί το σύστημα ανεβάζει την πίεση λειτουργίας του και όταν το πρόβλημα είναι μεγάλο ενεργοποιείται ο πρεσοστάτης υψηλής πίεσης διακόπτοντας τη λειτουργία του συστήματος προτού φτάσει τη ρύθμιση θερμοκρασίας που έχουμε ορίσει. Το σύστημα μπαίνει σε μια διαδικασία επαναλαμβανόμενων κύκλων λειτουργίας/ διακοπής χωρίς να καταφέρνει να φτάσει την επιθυμητή θερμοκρασία για την εφαρμογή.

Εάν λοιπόν παρατηρούνται υψηλές πιέσεις λειτουργίας το πρώτο που ελέγχουμε είναι αν είναι καθαρός ο συμπυκνωτής. Αν μετά τον καθαρισμό με νερό συνεχίζουμε να έχουμε το ίδιο πρόβλημα προχωράμε στο χημικό καθαρισμό του συμπυκνωτή. Μετά τον καθαρισμό μετράμε την υπόψυξη του συστήματος ώστε να βεβαιωθούμε ότι λειτουργεί ικανοποιητικά.

Η υπόψυξη είναι η διαφορά θερμοκρασίας μεταξύ της θερμοκρασίας συμπύκνωσης και της θερμοκρασίας του ψυκτικού ρευστού στην έξοδο του συμπυκνωτή. Τη θερμοκρασία συμπύκνωσης τη βρίσκουμε από την υψηλή πίεση λειτουργίας του συστήματος με τη χρήση πίνακα πίεσης/ θερμοκρασίας για το συγκεκριμένο ψυκτικό ρευστό της εφαρμογής. Τη θερμοκρασία εξόδου του ψυκτικού ρευστού από τον συμπυκνωτή την λαμβάνουμε με ένα θερμόμετρο. Αν η διαφορά αυτή είναι πολύ μικρή (μικρότερη από 2°C ) μπορεί να είναι ένδειξη έλλειψης ψυκτικού ρευστού ή άλλου προβλήματος.

Αντίστοιχα αν η διαφορά αυτή είναι πολύ μεγάλη (μεγαλύτερη από 6°C) θα μπορούσε να είναι ένδειξη υπερπλήρωσης του συστήματος ή κάπου άλλου προβλήματος που οδηγεί στη συγκέντρωση ψυκτικού ρευστού στο στοιχείο του συμπυκνωτή. Η υπόψυξη είναι απαραίτητη ώστε να αποφύγουμε την ύπαρξη αερίου στην είσοδο του εκτονωτικού μέσου καθώς κάτι τέτοιο θα μείωνε την απόδοση και την αποδοτικότητα του συστήματος. Θα πρέπει να λάβουμε υπ’ όψιν μας πως υπάρχει μια μικρή πτώση πίεσης σ’ όλα τα εξαρτήματα που παρεμβάλλονται μεταξύ του συμπυκνωτή και της εκτονωτικής βαλβίδας.

Οι συμπιεστές είναι γενικά πολύ αξιόπιστοι. Ωστόσο η ελλιπής συντήρηση ή τα προβλήματα άλλων εξαρτημάτων του συστήματος μπορούν να επηρεάσουν τον συμπιεστή με αποτέλεσμα την υπερθέρμανσή του. Είναι καλό να μετράμε την αντίσταση της περιέλιξης με ένα μεγγόμετρο ώστε να είμαστε σίγουροι ότι δεν υπάρχει βλάβη στον κινητήρα του συμπιεστή. Επιπλέον μπορεί να χρησιμοποιηθεί κάποιος αναλυτής συμπιεστή για περαιτέρω ανάλυση. Αν γίνει σύντομα αντιληπτή ενδέχεται η υπερθέρμανση να μην έχει επηρεάσει τον συμπιεστή. Αν όμως το πρόβλημα υπάρχει για μεγάλο χρονικό διάστημα ίσως απαιτηθεί να γίνει αντικατάστασή του.

Πολύ σημαντικός είναι ο τακτικός και σύμφωνα με τις οδηγίες και τα πρότυπα, έλεγχος απωλειών ψυκτικού ρευστού. Ο έγκαιρος εντοπισμός διαρροών βοηθά στο να έχουμε ελάχιστες απώλειες προς το περιβάλλον ελαχιστοποιώντας το ισοδύναμο CO2 αποτύπωμα της εγκατάστασης καθώς και τις ώρες που θα παραμείνει εκτός λειτουργίας με ότι αυτό συνεπάγεται για την ποιότητα των ψυχόμενων προϊόντων. Ανάλογα με την ποσότητα του περιεχόμενου ψυκτικού ρευστού καθώς και το είδος της ψυκτικής εγκατάστασης προκύπτει απ’ την τρέχουσα νομοθεσία ο αριθμός των υποχρεωτικών ελέγχων απωλειών που θα πρέπει να διενεργούνται από τον αδειούχο και πιστοποιημένο ψυκτικό που αναλαμβάνει τη συντήρηση.

Σε αυτό το σημείο πρέπει να τονίσουμε πως οποιαδήποτε εργασία προληπτικής συντήρησης, επισκευής, έλεγχος διαρροών, πλήρωσης ψυκτικού ρευστού ή καθαρισμού πρέπει να εγγράφεται στο βιβλίο service της μονάδας. Μέσα από αυτό το αρχείο ο τεχνικός είναι σε θέση να εξάγει ταχύτερα και ασφαλέστερα συμπεράσματα σχετικά με οποιοδήποτε πρόβλημα ή δυσλειτουργία παρουσιαστεί.

ΠΗΓΗ: Περιοδικό ΨΥΚΤΙΚΟΣ

%20(1)-1000x500.png)

-275x275.jpg)

-275x275.jpg)

-275x275.png)

-275x275.jpg)

-275x275.jpg)

-275x275.jpg)

-275x275.jpg)

-275x275h.jpg)

-275x275h.jpg)

-275x275h.jpg)

-275x275.jpg)

-275x275.jpg)

-275x275.jpg)

-275x275.jpg)

Σχολιάστε